turnkey SOLUTIONS PROVIDER FOR YOUR industrial boilermaking and general mechanics projects

Agility. Flexibility. Integration.

Our one-stop shop is built around 6 areas of expertise.

For each of your projects, we offer a robust, agile solution from conception to completion.

Our expertise

-

Conception

Meeting your needs from specifications, with 2D/3D engineering drawings or sketches

-

Industrial boilermaking

Specializing in stainless steel, steel and aluminum processing and the manufacture of complex equipment (special machines)

Stringent quality control

-

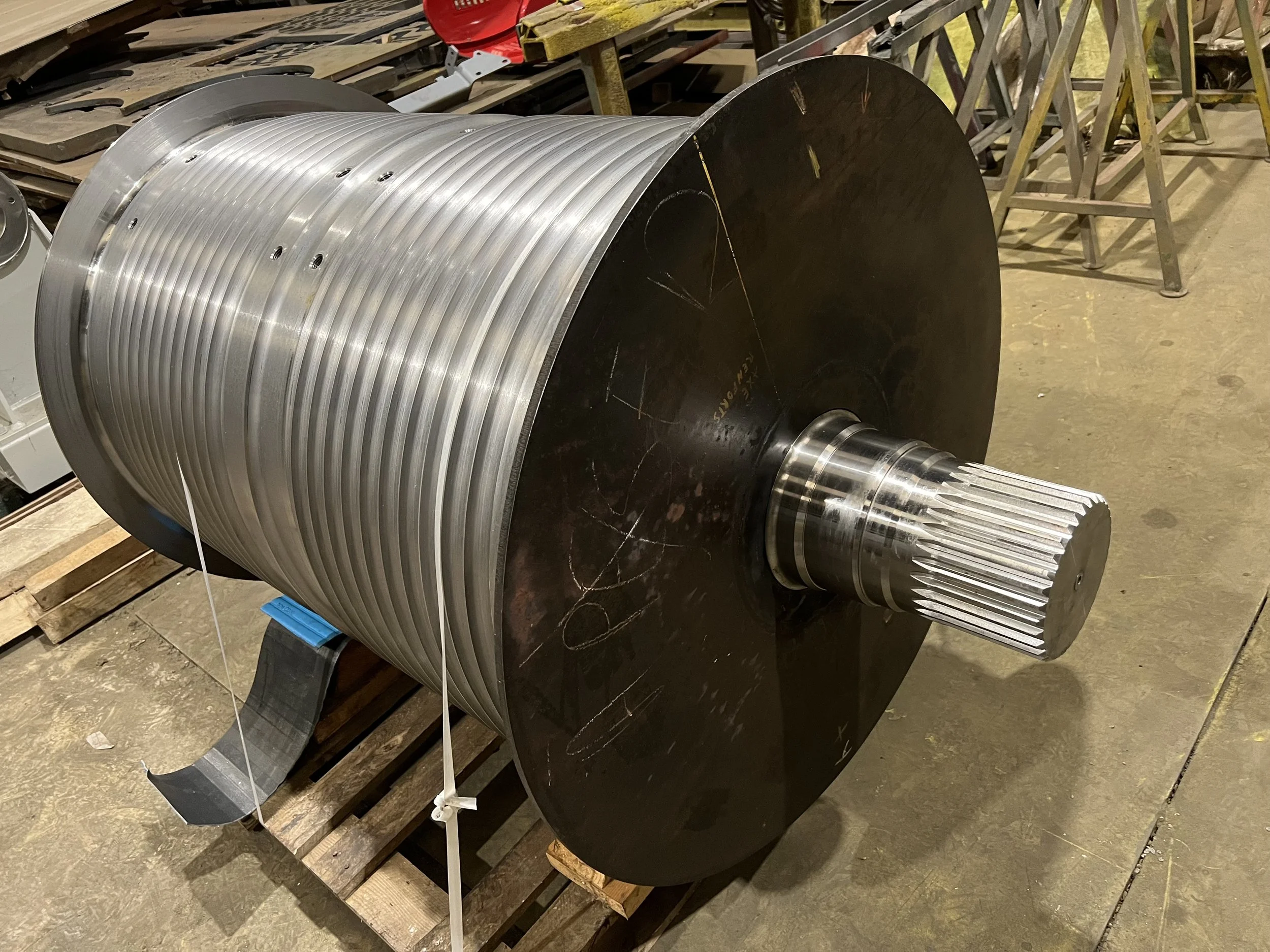

Precision machining

Machining of parts, from small to large series

All types of materials (aluminum, bronze, stainless steel, steel, etc.)

-

Sheet metal work

Profile bending, sheet metal rolling up to 40mm thick, long-length bending, all types of welding

-

Piping

Prefabrication of non-pressurized piping from stainless steel, steel — all diameters

-

Laser cutting

Small and large custom cutting of thin and medium parts (max. thickness 25 mm)

High-quality cutting, with low thermal distortion along the cutting zones

WE service industrial cLIENTS (energy, construction, agriculture, forestry, etc.) as well as individual customers (gates, BBQs, garden decorations, etc.).

EXAMPLES OF

OUR WORKS

For OVER 50 years, the workshop has been continuously evolving to adopt the highest performance tools to meet your needs.

Our tools

-

CUTTING

Laser cutting 2 000 x 4000 x 25 mm

Oxycutting 4 000 x 8 000 x 100 mm

Mechanical shear 6 mm x 4 000 mm

Mechanical shear 15 mm x 3 000 mm

Kaltenbach passage saw 610 mm

CN band saw 300 mm

-

SHAPING

Press brake C.N. 320 t x 4 m

Roller 3 mm x 2 000 mm

Roller 6 mm x 3 000 mm

Roller 25 mm x 3 000 mm

Profile bending machines

-

MECHANICAL WELDING

Modular mounting plates

MIG/MAG workstations

TIG station

-

MACHINING

CN parallel lathe, machinable diameter 480 mm x 4,000 mm

CN4 Axes lathe, machinable diameter 380 mm x 1 315 mm

CN vertical lathe, machinable diameter 2 100 mm x 1 600 mm

___________

CN milling machine 4 100 mm x 1 250 mm x 2 000 mm 4th axis, automatic head positioning

Traditional milling machine 1400 mm x 500 mm x 500 mm

OUR histoRY

OVER 50 YEARS' EXPERTISE IN INDUSTRIAL BOILERMAKING AND GENERAL MECHANICS

Founded in 1969 by Émile Jacquier in Frignicourt (Marne), JACQUIER is a family business with cutting-edge expertise in boiler-making, piping, general mechanics and precision machining.

The company designs, manufactures, and assembles customized industrial equipment for a wide range of customers in France and abroad.

Committed to innovation and developing the skills of its employees, JACQUIER has been able to adapt and invest in new high-performance equipment to meet market trends and the needs of its customers.

Since June 2023, JACQUIER has joined the HAFFNER ENERGY group after a fruitful collaboration initiated in 2017. In particular, JACQUIER was HAFFNER ENERGY's main subcontractor for the first industrialization stage of its innovative hydrogen and renewable gas production technology. The two family-run companies have strengthened their ties over the years and have decided to give new impetus to the business, by perpetuating and developing JACQUIER's activity in the Vitryat region.

Our production workshop: a 2,500 m² building, with 7 overhead cranes and a fleet of 20 machines

Philippe Haffner, co-founder and CEO of Haffner Energy, and former French President François Hollande look on as Joël Trichot, who's been with JACQUIER for 35 years, demonstrates a bending forming operation (Photo: Geoffrey Flamant).

OUR TEAM

Michel Alet - boilermaker

Alexandre Beltz - quality technician

Roch Bommier - general director

Andy Cantin - intern

Loïc Coene - miller, sketcher

Olivier Chaudron - mechanic fitter

Matisse Jacques - intern

Jimmy Leclaire - welder

Yoan Streicher - workshop lead

Joël Trichot - boilermaker

Contact us

33 rue Jean Moulin, 51 300 Frignicourt

commercial@sasjacquier.com

+33 (0)3 26 74 09 03

© 2025 SAS JACQUIER